The tire valve plays a crucial role in maintaining proper tire pressure and ensuring safe vehicle operation.

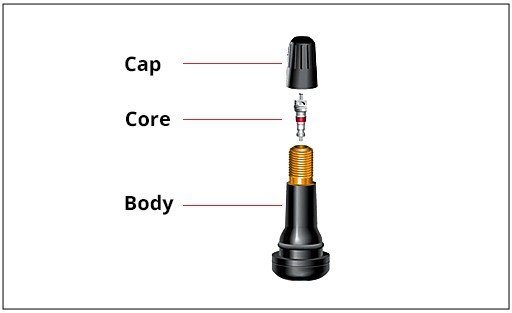

Tire Valve Parts

A typical tire valve consists of a core, cap, and stem.

Valve Core

The valve core sits between the cap and stem. It serves as the inner sealing portion of the valve stem and prevents air from escaping the tire.

Valve Cap

The valve cap prevents moisture and debris from contaminating the valve core. It can either be plastic or metal with a knurled or hexagon design.

Valve Stem

The valve stem is the component that houses the valve core. It comes with standard threads where the cap is screwed on.

Tire Valve Replacement

Experts recommend replacing the tire valve every time you get a new set of tires.

Although you can replace a valve stem without removing the tire, the stem’s rubber components can dry out and crack, which can lead to air leaks or total air loss.

Before you replace a tire valve stem, make sure that it’s the part that’s causing a leak and not the tire itself.

One way to check if the valve stem is leaking is by combining water and dish soap and pouring the mixture over the uncapped valve stem.

Bubbles forming at the end of the stem indicate a damaged tire valve.

In most cases, wear and tear could have damaged the spring-mounted mechanism inside the valve core.

Tire Valve Key Functions

1. Air Retention

- The valve seals air inside the tire, preventing leaks and maintaining consistent pressure.

- A valve core inside (usually a Schrader valve) allows air to enter but blocks it from escaping.

2. Inflation & Deflation

- Enables adding air (via an air pump) or releasing air (using a tool or the valve core depressor).

- Essential for adjusting pressure based on load, temperature, or driving conditions.

3. Pressure Monitoring (TPMS)

- In modern vehicles, the valve may integrate with the Tire Pressure Monitoring System (TPMS), sending real-time pressure data to the driver.

- TPMS valves have sensors that alert if pressure is too low.

4. Protection Against Contaminants

- A valve cap (usually plastic or metal) keeps out dust, moisture, and debris, preventing corrosion or clogs.

- Missing caps can lead to slow leaks or valve damage.

5. Structural Support

- The valve stem (rubber or metal) must withstand centrifugal force, road vibrations, and temperature changes without breaking.

Common Valve Types:

- Schrader Valve – Standard in cars, motorcycles, and bikes; robust and easy to service.

- Presta Valve – Common in high-performance bikes; narrower and lighter.

- Tubeless Snap-in Valve – Used in modern tubeless tires; has a rubber base for a tight seal.

Signs of a Faulty Valve:

- Slow air leaks

- Cracked or damaged stem

- Broken or missing valve cap

- TPMS warning light (if equipped)

Maintenance Tips:

✔ Check tire pressure monthly.

✔ Replace worn valves during tire changes.

✔ Always use valve caps to prevent leaks.

A faulty valve can lead to poor fuel efficiency, uneven tire wear, or blowouts, so regular inspection is vital.

Would you like details on valve replacement or troubleshooting?